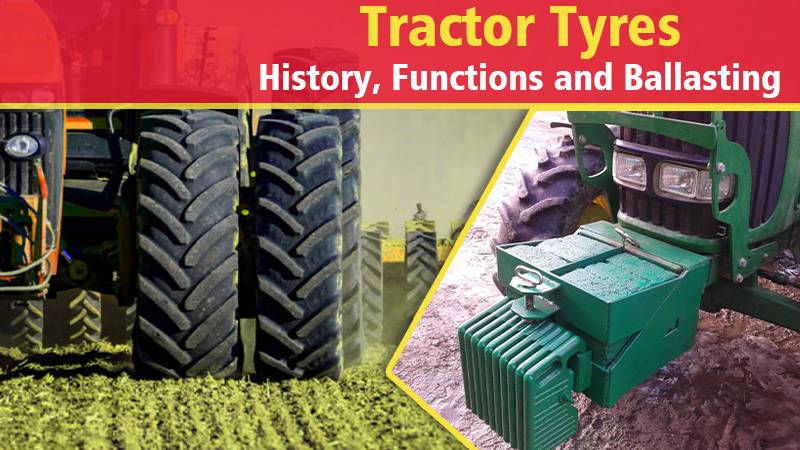

A Tractor tyre made from complex adaptable built-up composite material encompassing a steel center point and topped off with air under tension. It has much-extended ribs on the moving track. Various types of tyres are used in the tractor industry, here we are going to discuss some basic facts about tractor tyres, just have a look.

History of Tractor Tyre –

The steel-wheeled tractor tyres were introduced with pneumatic tyres during the 1920s and 1930s.

Harvey Firestone (1868-1938) was instrumental in creating support, “low-pressure” tyres that were appropriate for farming fieldwork. The Second War came about in deficiencies of normal elastic recently utilized for tyre creation.

This sped up the innovative work of manufactured rubbers like styrene and latex. The engineered rubbers delivered would be advised to wear safe properties than the first elastic tyres.

Manufactured rubbers that are commonly utilized today incorporate polyurethane, neoprene, polybutadiene, and butyl. Normal elastic might in any case be utilized for some applications.

Tractor Tyre Functions –

- Support the vehicle and related burdens at some low degree of ground pressure,

- Retain shock loads and pad the vehicle against minor surface inconsistencies,

- Give footing/traction effect for steering operations and provide stability to tractor

- Oppose the rough activity of the different surfaces on which it is relied upon to work.

Tyre Sizes and Types –

The development of rough terrain tasks has achieved an extraordinary enhancement in tyres to meet all assistance prerequisites.

The number of sizes– Tyres have expanded both in cross-area and in edge distance across. Bigger tyres license higher burdens per tyre without forfeiting floatation.

Ordinary versus wide base– Two kinds of tyres now exist to be the specific, traditional and wide base. Without changing the edge breadth or tyre in general measurement, the cross-segment width can be expanded by utilizing a more extensive edge.

With a similar tyre stacking, expansion pressures on the wide base tyre can be decreased. The more extensive cross-segment gives further developed foothold and floatation and the lower unit ground tension can work on the protection from harm from stones and different items.

Low area heightened tyres– The wide base guideline can be stretched out into low area stature tyres.

The low area heightened shape makes conceivable a more extensive cross-segment for further developed floatation without expanding breadth or tyre weight, as would have been fundamental if customary tyre shapes had been kept up with.

Single versus double– One more utilization of low-segment stature standard is in the utilization of bigger straightforward tyres to supplant double tyres.

Although the change from double tyres to an enormous single tyre lessens the all-out ground contact region, experience has shown that floatation and portability are improved without decrease altogether load conveying limit.

Track design– All off-roadway activities needn’t bother with a similar level of footing. Accordingly, separate track patterns are utilized for various levels of tractive exertion.

Track/Tread on Tractor Tyres-

Size (distance across and width) decides their tractive limit and moving obstruction.

Strength, communicated as far as handle rating, which thus decides the strain that can be utilized and consequently the weight that the tyre can convey; this thusly additionally decides the tractive limit and the moving opposition.

Track design, along with the surface attributes, decides the commitment and/or contact with the surface.

The misfortunes in influence in the surface interface are regularly extraordinary, especially on delicate surfaces (ie, their proficiency is low), henceforth the influence accessible at the tractor drawbar might be considerably less than the influence of the motor.

Subsequently, the decision of the tyres and the load on them is urgent in deciding the general performance of the tractor.

Tyre Types According to Surface Condition-

- Hard surfaces like streets – Large region, shallow track with ‘high’ pressure tyres required

- Typical rural work, dry soil-Heavy, transitional profundity track tyre required

- Delicate, wet rural soils – Deep track tyre required

- Yards, low sinkage is required – Wide, low tension tyre required

- Dry soil, substantial burdens as in earth moving – Tracks, as on a “crawler” tractor tyre required

- Immersed puddle soils – Metal enclosure, with calculated carries, alone or as augmentations to typical tyres required

Ballasting in Tractor Tyres–

The tractive effect of a tractor can be improved, especially on sandy soils, by ballasting, which adds weight to the drive wheels. It is significant, notwithstanding, that the tyre producer’s recommended load, at typical swelling pressures, not be surpassed.

The option of stabilizer to a tractor is typically refined by adding wheel loads, adding front loads, and filling the tyres with water.

Adding a lot of stabilizers will bring about extreme force misfortune because of expanded moving obstruction, however, inadequate counterbalance will cause influence misfortune due to the expanded wheel slip.

Download KhetiGaadi Mobile Application for more details about tractor tyres and the tractor Industry.

Visit our page for more information about Tractor, Agricultural implements, Tractor Price, Tractor Videos, and Tractor Games.