Traditional methods of leveling land in the agricultural sector are cumbersome, time-consuming, and expensive.

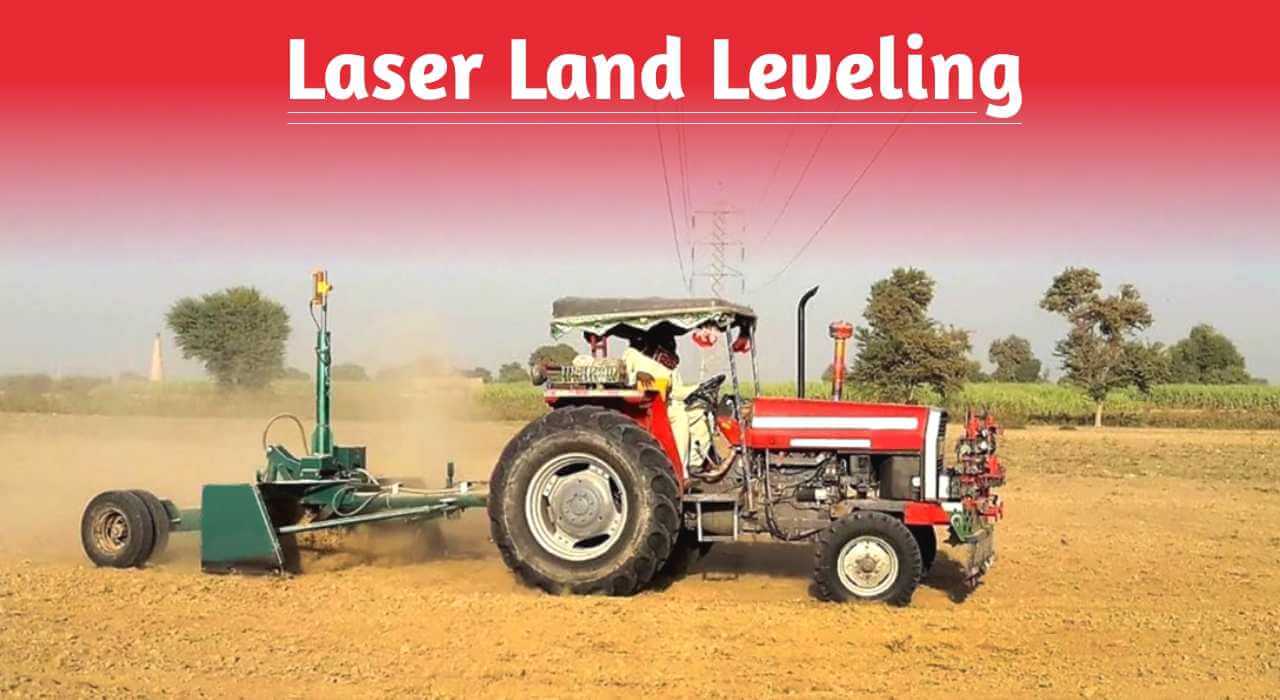

Nowadays more and more farmers are turning to modern methods to level the land. Laser leveling is a process of smoothing the land using tractor operator implements. In this

practice use of large HP tractors and soil movers take place.

They are equipped with laser‐guided instrumentation so that the soil can be moved either by cutting or filling to create the desired slope/level.

This technique is well known for higher levels of accuracy in land leveling. This method offers great potential for water savings and higher grain yields.

Benefits of Laser Land Leveling

- The leveled surface of farmland helps to uniform soil moisture distribution, resulting in good germination, enhanced input use efficiency, and improved crop yield.

- This method helps in the control of water distribution with minimum water losses.

- This method improves irrigation efficiency and reduces nutrient loss by better runoff control.

- Uniformity in the placement of seedlings to achieve higher yields.

- Land leveling reduces weed, pest, and disease problems to help in the improvement of better-quality agricultural produce.

- Help in additional land recovery and improves operational efficiency.

- Help to reduce the consumption of seeds, fertilizers, chemicals, and fuel in farmland.

- Easy movement of agricultural machinery through the agricultural field

Limitations of Laser Land Leveling

- The high cost of the equipment increases the initial investment cost.

- Skilled operator required to set laser settings and operate the tractors with that

- This method is not suitable in irregular and small‐sized fields

How Does a Laser Leveler work?

In this method, the laser transmitter transmits a laser beam. It is intercepted by the laser receiver mounted on the leveling bucket. The control panel for that system rested on the tractor. The Control panel interprets the signal from the receiver and opens or closes the hydraulic control valve. Loose soil particles are picked up by the bucket and released lower in the field.

4‐wheel tractor

A 4‐WD tractor is required to drag the leveling bucket. The power of the tractor could be varied from 30‐500 hp depending on the agricultural field sizes.

4WD drive with power shift transmission is preferable for this operation.

Drag bucket

Bucket used for leveling can be either 3‐ point linkage mounted or pulled by the tractor’s drawbar.

Pull type systems are easy to operate as it is easier to connect the tractor’s hydraulic system to an external hydraulic ram, so pull-type systems are most preferable for this operation

Laser transmitter

The laser transmitter rest on a tripod. It allows the laser beam to sweep above the tractor unobstructed. Several tractors can work with one transmitter.

Laser receiver

It detects the position of the laser reference plane. Then it transmits these signals to the control box. The receiver rest on a mast attached to the drag bucket.

Control panel

The main control box accepts then processes signals from the machine‐mounted receiver. It indicates the drag bucket’s position relative to the finished grade.

Hydraulic control system

This system supplies oil to raise and lower the leveling bucket. The main function of the pressure relief valve in the system is to return the excess oil to the tractor reservoir.

If the relief valve is not large enough or it malfunctions, damage, in that case, can be caused to the tractor’s hydraulic pump.

Different Types of Laser Levelers

Manual leveling lasers ‐ In this type of setup of a laser leveling instrument requires the operator to manually level the unit by using the units’ screws and bubble vials. These lasers can achieve maximum accuracy of 1 cm at 100m.

Semi self‐leveling lasers

These types of lasers adjust themselves automatically within a range. They can achieve an accuracy of at least 1 cm at 100 m. They are equipped with a circular bubble with a bull’s eye or electronic lights that turn green when you reach the self‐leveling

range.

Fully self‐leveling lasers

These types of lasers automatically find and maintain the level within a specified range. They are the easiest to use. They can achieve an accuracy of up to 2.5 mm at 100 m.

Split‐beam lasers

These types of lasers emit simultaneous horizontal and vertical beams to establish both level and plumb reference lines.

Conclusion

Modern farming methods like laser levelers always help to farmers to increase productivity and improve the quality of crop yield. All different implement brand types of laser levers are available at Khetigaadi.com with laser leveler prices in India and technical specifications. Just have a look.

Visit our page for information about Tractor, Agricultural implements, Harvesters, Tractor Price, Tractor Videos, and Tractor Games.